Diecasting is the usage of molds, known as dies. Dies are created from high-quality steel to withstand the tough conditions encountered in the casting process. Die designs are made to be precise, and usually incorporate intricate details and fine tolerances in order to guarantee the final product's accuracy. In the process of diecasting, melting metal - commonly aluminum, zinc or magnesium-is introduced into dies with extreme pressures. This quick injection and subsequent the process of solidification results in parts with high dimensional stability and polished surface, which reduces the requirement for additional machining or finishing. Precision of the dies allows for the production of geometries with complex shapes that are difficult or impossible to attain using conventional manufacturing techniques.

One of the most significant advantages of diecasting is the ability to produce mass quantities. When dies are manufactured the dies can then be utilized for the production of thousands of identical components that have minimal variations. The high degree of repeatability is crucial for businesses which require huge quantities of consistent components. In addition, diecasting is renowned for its material efficiency. The process generates minimal scrap, because any excess metal is re-usable to make casting cycles in the future. This is not only a way to reduce costs for materials, but it also encourages sustainable manufacturing practices by minimizing production waste while also conserving resources. A combination of productivity, speed of production in material performance makes diecasting a desirable option in the quest to maximize the efficiency of their processes.

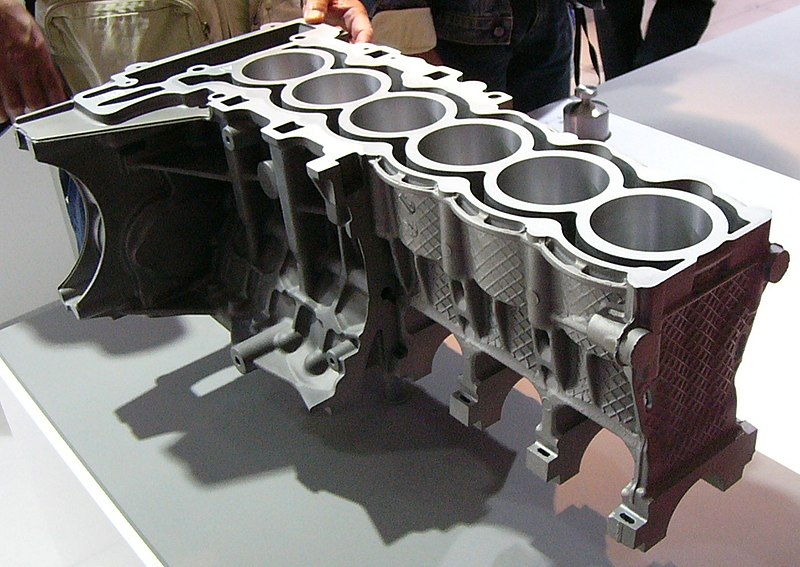

Diecasting is widely employed across various industries due to its flexibility and variety of different materials employed. For automotive manufacturing Diecasting is a must in the production of components such as motor blocks, transmission casings as well as structural components. The aerospace industry relies upon diecasting for light components that are strong enough to stand up to the rigorous conditions of flying. In electronics for consumers, diecasting components are employed for frames and frames that provide high-quality and precise devices. Diecasting's versatility expands to the communications, medical, and power tool industries, demonstrating its broad utility and importance. To generate added information kindly look at https://www.senadiecasting.com.my/

The materials you choose for diecasting significantly influences the properties and efficiency of the final product. Aluminium is an extremely popular material because of its superior strength-to-weight ratio, resistance to corrosion, along with its excellent electrical and thermal conductivity. Aluminum's properties make it ideal for aerospace and automotive uses that require weight reduction. Zinc alloys have high strength as well as ductility. These make them appropriate for products that need fine detail and long-lasting. Magnesium alloys are the lightest structural metals, providing benefits in situations where weight reduction is crucial. Copper alloys, although used less frequently but are coveted for their high electrical conductivity and the resistance to corrosion. Each alloy has distinct advantages that allow manufacturers to choose the most suitable option to meet the specific requirements of their application.

Diecasting is a highly sophisticated manufacturing process that brings together accuracy, precision and flexibility. The ability of diecasting to create sophisticated, high-end components that have excellent mechanical properties makes it indispensable in many sectors. Diecasting's efficiency as a mass-production process, coupled with its material and cost advantages, proves its worth in the modern world of manufacturing. While industries are continuing to require top-quality and durable components that are durable and reliable, diecasting will be an essential technology that drives advancement and the creation of innovative products that fulfill the constantly changing demands of the market. Due to its continuous growth and development diecasting illustrates the interplay of excellence in engineering and manufacturing expertise.